SIAA Columnist Part 4: The Industry 4.0 Framework

Industry 4.0 is many things to many people. For our purposes, Industry 4.0 is a journey deeply involving various advanced technologies that help manufacturing operations become more reliable, productive, efficient, and customer-centric. Another useful definition of Industry 4.0 (among a multitude of others) is the information-intensive transformation of manufacturing and other industries. The Industry 4.0 environment digitally connects data, people, processes, services, systems, and IoT-enabled industrial assets across cyber and physical worlds. The goal is to create, use, and take full advantage of actionable information. For some analysts, Industry 4.0 describes a future state of industry characterised by thorough digitalised production processes. For others, Industry 4.0 is already here, representing a new and higher level of organisation and control over manufacturing along entire value chains and product life cycles. There are many Industry 4.0 frameworks. Each country engaged in systematically modernising its manufacturing base has its own. As in Japan (Society 5.0), the scope of the framework might expand beyond manufacturing. National development priorities might focus on different sets of advanced technologies. However, countries engaged in Industry 4.0 programs and initiatives tend to emphasise a standard model, a set of advanced technologies, and concepts.

Technology Pillars of Industry 4.0

Industry 4.0 depends on not one but several advanced technologies. Some are familiar; others have been a commercial product for a short time. It’s the combination of these technologies in R&D, production, and post-production processes that will help make manufacturing more efficient. Different analysts use slightly different lists of technologies.

However, these are the technologies usually mentioned in Industry 4.0 frameworks:

• Big data/advanced analytics — The industrial world is filled with mountains of unanalysed product and process data. Analysing it and turning it into actionable information can optimise production quality, improve services, and enable faster and more accurate decision making.

• Advanced robotics — As robots become more flexible, cooperative, and autonomous, they will interact with one another, work safely with humans, and eventually learn from humans, too. Industry 4.0 provides a manufacturing context for these opportunities.

• Advanced simulations — In Industry 4.0 environments, 3D simulation of product development, material development, and production processes will enable operators to test and optimise processes for products before production starts.

• AI/cognitive computing — Cognitive manufacturing uses the assets and capabilities of the IoT, advanced data analytics, and cognitive technologies such as AI and machine learning. When used together these technologies will drive improvements in the quality, efficiency, and reliability of manufacturing processes.

• Industrial Internet of Things — In the IIoT, an ever-greater number of products will incorporate internet-connected devices, which link with each other with standard protocols. This approach to manufacturing will decentralise analytics and decision-making and enable real-time responses.

• Cybersecurity — Industry 4.0 environments include connectivity and communications protocols as well as sophisticated identity and access management systems. These technologies enable manufacturers to provide secure, reliable communications and data flow throughout Industry 4.0 systems.

• Additive Manufacturing — In Industry 4.0 manufacturing environments, these technologies are the best choice for producing small-batch, customised, and high-performance products.

• Cloud-based service-enabling technologies — Industry 4.0 manufacturing operations require more data sharing across sites and companies than earlier processes do. Shifting data storage and management to the cloud will drive the development of more manufacturing execution systems (MESs) that use cloud-based machine data.

• Augmented reality -- AR provides an effective way to represent production processes by overlaying real-world views of production with virtual information. In ASEAN countries, the most likely role of AR lies in training future workers and technicians how production systems behave in real-time. Emerging Technologies demonstrate the breadth of applications that make up Industry 4.0. In the world of Industry 4.0, technology doesn’t operate in isolated factories or assembly lines. In fully realised Industry 4.0 environments, technologies connect with other entities, up and down production hierarchies, along value chains, and throughout product life cycles.

The RAMI 4.0 Model

The Reference Architectural Model Industrie 4.0 (RAMI 4.0) was developed in Germany as part of the country’s Platform Industrie 4.0 initiative. As Industry 4.0 achieved more acceptances throughout Europe and beyond, the need for a clear and consistent vocabulary became increasingly important. The RAMI 4.0 goal was to create a uniform framework for national and international communications and ideas.

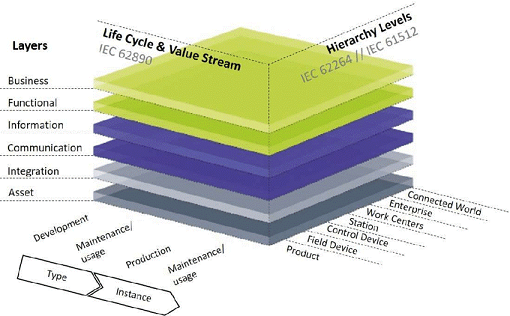

RAMI 4.0

Structure Targeting at a collective understanding of Industry 4.0, RAMI 4.0 is an idea map that describes manufacturing processes and production objects in a clear and systematic way. RAMI 4.0 ensure that those involved in discussions of Industry 4.0 will understand one another. In this model, each production object is defined with its related functions and data. The result is a complete, virtual description of the object. The RAMI 4.0 structure is built on a three-dimensional framework consisting of the Value stream and life Cycle, Hierarchy Levels and Layers.

Dimension 1: Life cycle and value stream. In RAMI 4.0, each product is described and tracked from the first idea to the scrap yard by Life cycle axis based on IEC62890 standard. First of all, a specific product type consists of an identifier, meta data and associated certificates, while a product instance behaves as the instantiation of a product type, characterised by an instance identifier. Based on this definition, the life cycle of a product will detail the life cycles of both product type and instance. According to Rami 4.0 model, product type life cycle starts from the development phase throughout maintenance & usage stage. On the other hand, the product instance life time model starts from the production phase throughout usage stage which includes commissioning and disassembling or disposal of the instance.

Dimension 2: Hierarchy levels. The foundation of the axis description is IEC62264 and IEC61512 (also well known as ISA95 and ISA-88), representing different functional levels of a factory. To make it easier to talk about complex production processes, engineers and plant managers divide them into several categories, including the connected world, enterprise, work centres, machines (workstations), control devices field devices and products.

Dimension 3: RAMI interoperability layers. This dimension represents different types of data and functions relevant to elements of Dimensions 1 and 2. These data and functions include business layer, functional layer, information layer, communication layer, integration layer and asset layer.

With precisely defined contexts for Industry 4.0 ideas and production objects, users can work their way through the model knowing that other users have the same information, vocabulary, and contexts.

The RAMI 4.0 Standards

Developing consistency across RAMI users is essential to gain the most from the framework. For this, standards must be developed, adopted, and integrated into systems. In RAMI 4.0 context, there are a few standards that have been leveraged, expanded and presenting integrated value for Industry 4.0 development.

IEC 62264 : IEC 62264 showcased in RAMI 4.0 architecture model is a standard for enterprise-control system integration, built on the well-known ANSI/ISA-95. ISO/IEC 62264 is an integral part of the RAMI model for Industry 4.0 development and has been singled out as a key standard for the factory of the future initiatives.

IEC 61512: Good note to be taken is the IEC61512 which is commonly referred to as ISA-88 (IEC-61512-1) addressing batch process control with the description on equipment and procedures.

IEC 62890: As explained in the reference structure, IEC 62890 represents life-cycle management for the systems and products used in industrial process measurement, control and automation.

About the Columnist

Industry veteran Colin Koh is our monthly columnist to share with SIAA community the essence of ASEAN manufacturing and pragmatic tips on how to approach and navigate the fourth industrial revolution for their businesses. Stay tune to Colin's regular segment all about Smart Manufacturing 4.0 in ASEAN! Please visit www.asean4ir.com more resource.